| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : ZTIC

Model Number : Customized

Certification : ISO,CE,RoHS

Place of Origin : Henan, China

MOQ : >=1 Sets

Price : $3,000.00

Payment Terms : Western Union, MoneyGram, L/C, D/A, D/P, T/T

Supply Ability : negotiable

Delivery Time : 1month

Packaging Details : Standard packing or according to customer's requirement

Name : Small pinion gear

Material : Steel

Processing Type : Casting

Condition : New

Type : Pinion gear

Machine Type : Rotary kiln and ball mill

Certificate : ISO9001:2015

Surface treatment : Painting

OD For Gear Wheel : MAX.13 000 mm

Key words : Pinion,pinion gear,small gear

Height For Gear Wheel : el: MAX. 1200 mm

Port : QingDao,ShangHai,TianJin

Pinion gear material

42CRMO STEEL DATA

CHEMICAL LIST

C : 0.38-0.45%

Si: 0.17-0.37%

Mn: 0.50-0.80%

S : Allow residual content <0.035%

P : Allow residual content <0.035%

Cr: 0.90-1.20%

Ni: Allow residual content <0.030% Cu: Allow residual content <0.030%

Mo: 0.15-0.25%

MECHANICAL DATA

Tensile Strength σb (MPa): >1080(110)

Yield point σs (MPa): >930(95)

Elongation σ5 (%): >12

Reduction of area ψ (%): >45 Akv (J): Impact absorbing energy Akv(J): >63

Impact toughness value αkv (J/cm2): >78(8)

Hardness: <217HB

Sample size: The blank size of the sample is 25mm

PHYSICAL DATA

Critical point temperature (approximate value): Ac1=730ºC, Ac3=800ºC, Ms=310ºC

Linear expansion coefficient: temperature: 20~100ºC/20~200ºC/20~300ºC /20 ~400ºC/20~500ºC /20~600ºC

linear expansivity: 11.1x10K/12.1x10K/12.9x10K/13.5x10K/13.9x10K14.1x10K

Ball Mill Pinion Gear

Ball Mill Pinion Gear

| item | remark |

| normall materials of pinion gear | 35crmo, 42crmo |

| better materials of pinion gear | 17crnimo6, 20crmnmoA |

Ball Mill Pinion Gear

Ball Mill Pinion Gear

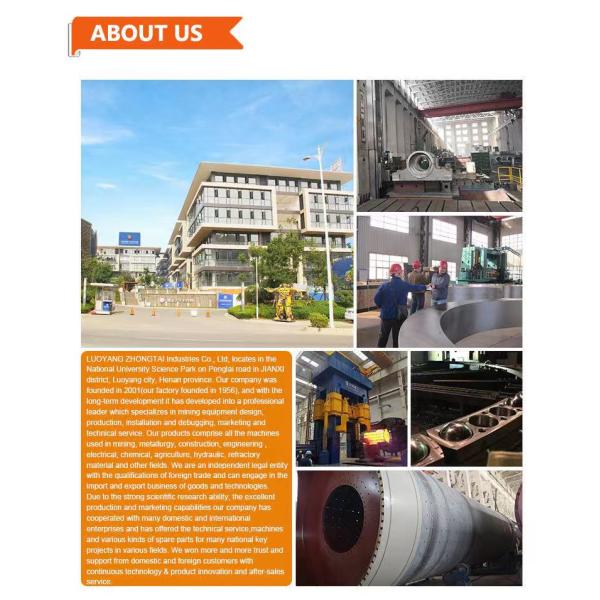

company show

Ball Mill Pinion Gear

FQA

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time :

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms :

A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

|

|

Carburizing Steel Forging Spur 18CrNiMo7-6 Ball Mill Pinion Gear Images |